We tell you how our skills and experience could help companies to optimise their work processes. Here's an example!

RFID TECHNOLOGY AND ITS ADVANTAGES

The adoption of RFID technology (Radio Frequency IDentification) has a significant impact on all work processes because it allows a huge amount of products to be identified and tracked quickly and securely.

WHAT DOES IT MEAN TO IMPLEMENT A RFID PROJECT?

Realizing a RFID project is not just a matter of choosing the correct tags, but it means to re-deploying an entire work process to integrate with existing and different systems.

Each project has its own identity, which requires a detailed analysis and a specific solutions range.

For this reason each job has it own story

here we would like to tell you one.

OUR PROJECT

This project was born out of a desire to respond to a need that emerged within the large warehouse of an important italian forniture manufacturer, which has been operating in this sector for over 70 years.

In collaboration with bigblue and our dealer, De Biaggi & Baratella, we designed a fully functional RFID prototype solution for their needs.

The customer, who also deals with the goods production and storage, needed to:

- reduce working time and costs

- manage the handling of large trolleys of coded wooden panels

- track material and manage shipments up to the last load and to the final customer

- identify products with reusable RFID labels

- implement this technology also for the inventory (simultaneous reading)

WHAT HAS PLURISERVICE DONE?

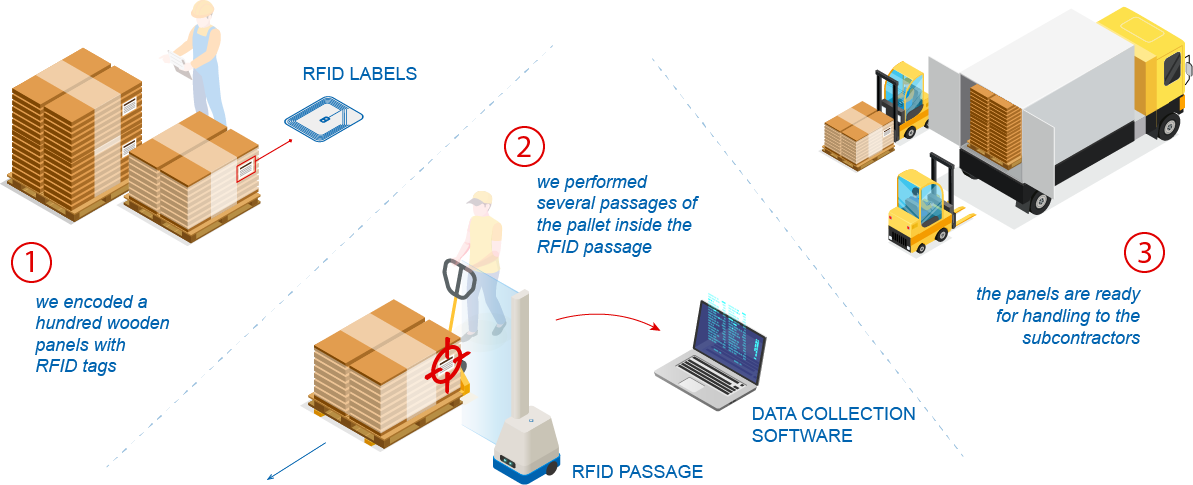

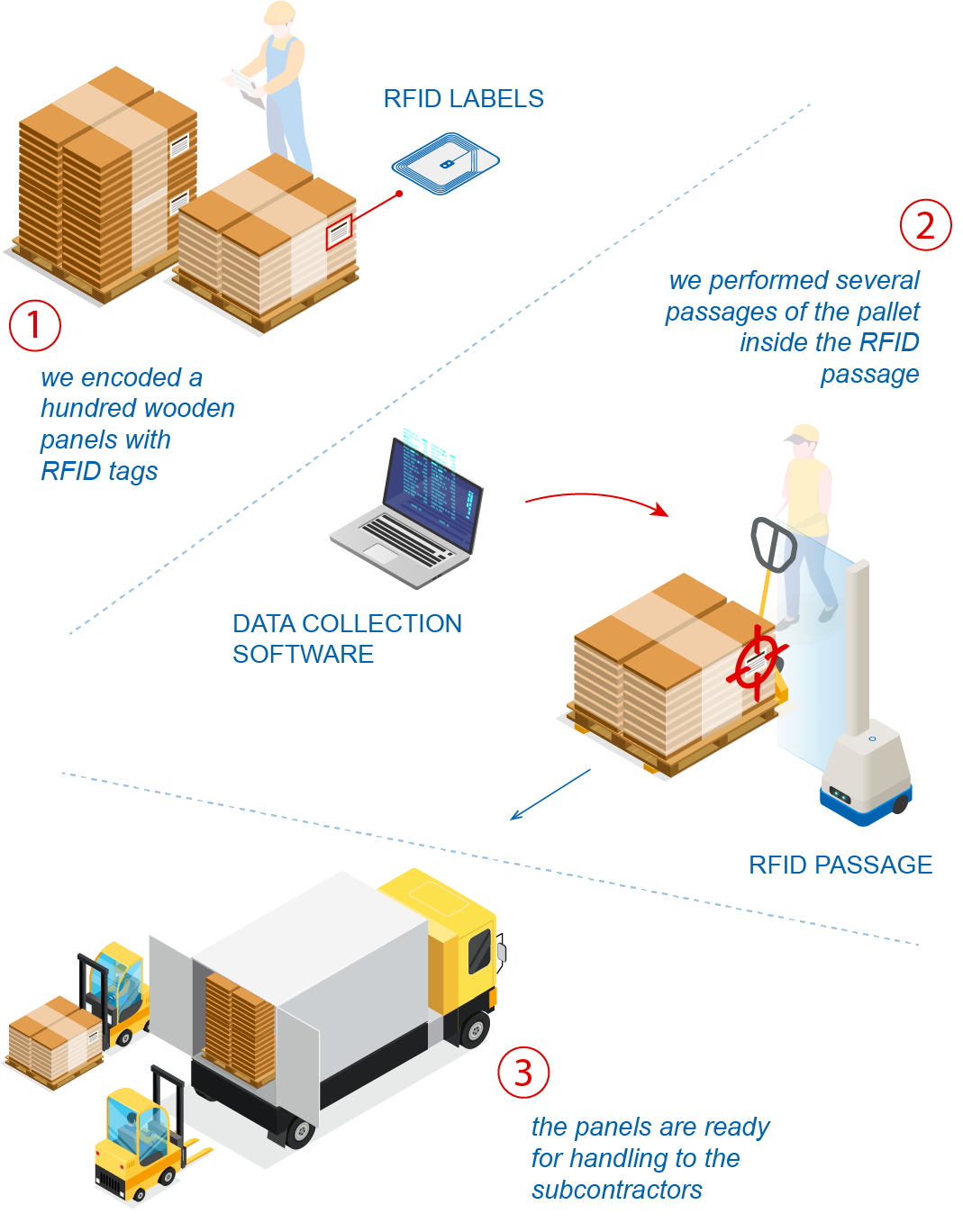

In their warehouse we set up an RFID passage with 4 antennas, a control unit and the software to collect the data read.

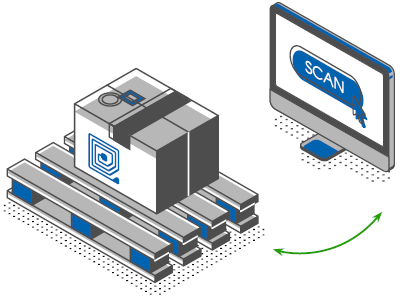

After encoding about a hundred of heavy wooden panels, each with a RFID label containing printed data, we placed the panels one over the other on a pallet truck. We performed several tests with multiple passes of the pallet truck through the RFID passage with an increasing amount of products.

The results of the experiment were very positive, in just a few seconds this solution was able to identify all the goods and their data in the tags.

All the labels used during the trials were produced by Raining Labels, a Pluriservice Group’s company. Resistant to all temperatures, reusable and foldable, with visible data on the external side as barcode, qrcode..

Pluriservice deployed its technical and qualitative skills, one again confirming the Group’s market leadership.

WHAT HAS PLURISERVICE DONE?

In their warehouse we set up an RFID passage with 4 antennas, a control unit and the software to collect the data read.

After encoding about a hundred of heavy wooden panels, each with a RFID label containing printed data, we placed the panels one over the other on a pallet truck. We performed several tests with multiple passes of the pallet truck through the RFID passage with an increasing amount of products.

The results of the experiment were very positive, in just a few seconds this solution was able to identify all the goods and their data in the tags.

All the labels used during the trials were produced by Raining Labels, a Pluriservice Group’s company. Resistant to all temperatures, reusable and foldable, with visible data on the external side as barcode, qrcode..

Pluriservice deployed its technical and qualitative skills, one again confirming the Group’s market leadership.

RESULTS ACHIEVED

After a detailed analysis of the test we found that this solution allows a 100% automation of warehouse loading and unloading and it estimates a saving of around 5000 hours-man per year for the company.

This means, in addition to a fairly high cost reduction, greater efficiency and speed in meeting customer requirements.

FINAL GOAL

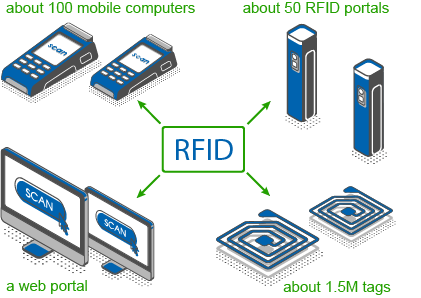

The ultimate goal provides the implementation of this solution for another 8/10 establishments that will deploy around 50 RFID portals, 1.5 milion tags and a houndred of mobile computers for code reading.

Finally our partner, bigblue, will implement a web portal for the management of all work processes, so that the company can keep track all the work progress of its subcontractors.

This will allow an error reduction and a greater accuracy and reliability.